Transformer AMC Services

At Trafo Power, we pride ourselves on being one of India’s leading manufacturers and suppliers of power and distribution transformers and their components. We cater to diverse sectors, including residential, industrial, and power transmission units. To ensure the highest quality, performance, and reliability, we offer comprehensive Transformer Annual Maintenance Contract (AMC) Services.

Why Transformer AMC Is Essential

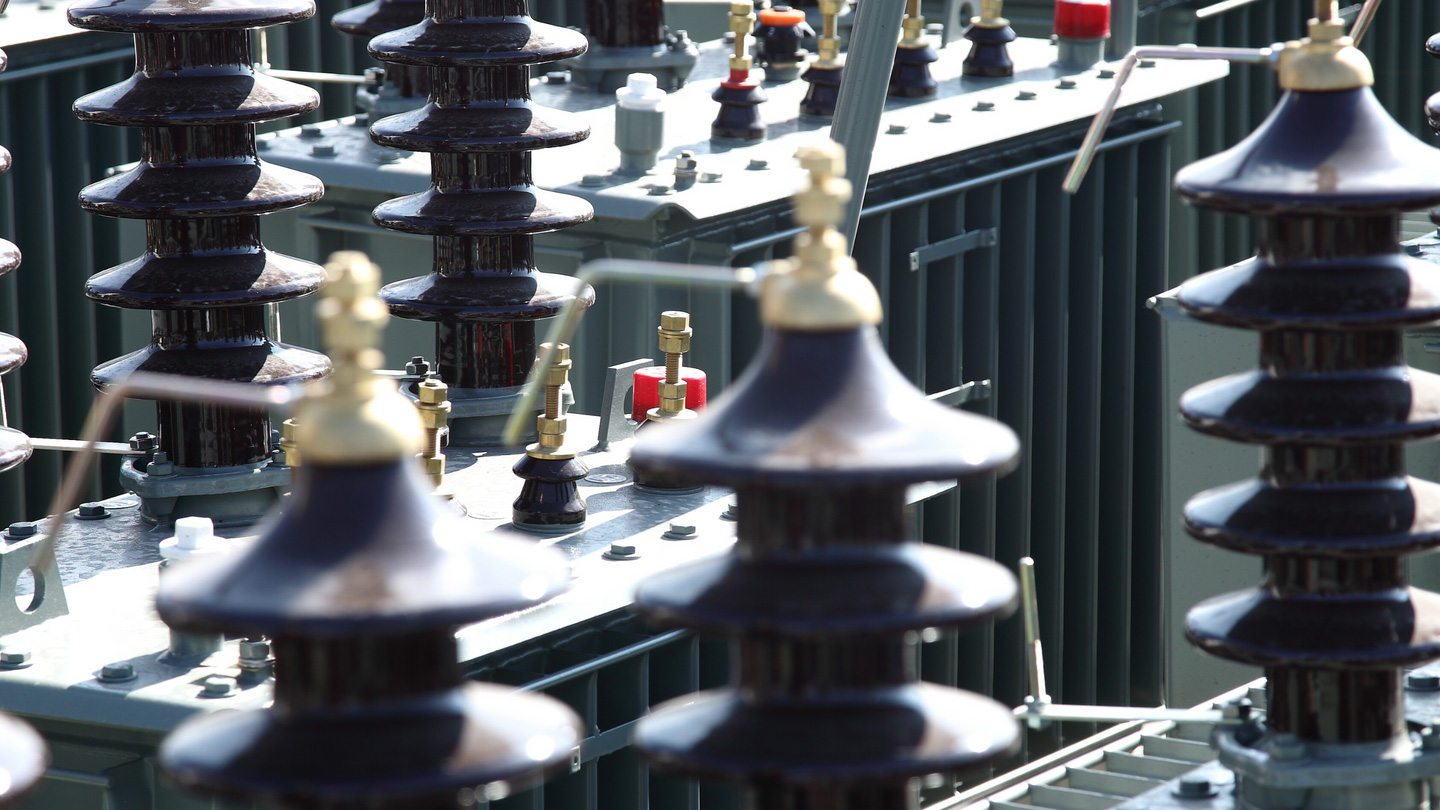

The ever-growing demand for reliable power supply calls for continuous innovation in transmission systems and meticulous maintenance of their components. Transformers, being high-performance machinery, operate under extreme conditions and play a critical role in seamless power distribution over long distances.

To maintain their optimal performance, safety, and longevity, regular inspections and preventive maintenance are essential. This is where our AMC services become invaluable—helping customers avoid power outages, reduce downtime, and prevent short circuits caused by neglect or lack of monitoring. Whether installed in commercial facilities, residential areas, or power substations, our AMC services offer the perfect solution for reliable and efficient transformer maintenance.

What Our Transformer AMC Services Include

Trafo Power’s AMC services are comprehensive, covering all aspects of transformer maintenance to ensure optimal performance, safety, and durability. Below are the key features of our contract:

1. Inspections

2. Preventive Maintenance

3. Oil Analysis

4. Load Management

5. Protective Maintenance

6. Documentation

7. Emergency Support

In case of breakdowns or failures, our emergency support team is available to address issues promptly. Faulty components such as tap changers, bushings, and fuses are repaired or replaced as needed.

What Sets Trafo Power’s AMC Services Apart

As a trusted name in the transformer industry, Trafo Power offers end-to-end solutions—from delivering high-quality transformers to providing proactive and reliable maintenance services.

Here’s why our AMC services stand out:

Future-Ready Solutions: IoT-Enabled Monitoring and Preventive Maintenance

At Trafo Power, we are committed to staying at the forefront of technological advancements in the transformer industry. As part of our future vision, we are developing IoT-enabled monitoring and preventive maintenance services for transformers.

Through this innovative approach, customers will gain real-time access to critical transformer data, allowing for better performance tracking, early fault detection, and proactive maintenance planning. By leveraging IoT technology, our customers will be able to:

This service will not only provide a proactive maintenance approach but also improve the overall lifecycle and reliability of transformers.

SERVICES WE PROVIDE

| QUARTERLY VISITPAGE | YEARLY VISIT |

|---|---|

| Inspection of Oil Level | All services are include of Quarterly visit |

| Oil Leakages if any | Taking out main cover / inspection window, sludge removing by oil jet |

| Breather Condition | Inspection of tap changer, conservator, oillevel indicator replace |

| Inspection of HV & LV insulator Examine for cracks and dirt deposit | Oil filtration for improving B.D.V. & I.R.values, improve acidy level of oil |

| Metal parts checking | Attending oil leakages if any |

| Inspection of OTI, WTI, PRV, B.Realy,OSR, Explosion Vent etc. | Replacement of all HV & LV rubber/ corkgaskets and oil seals |

| Radiators ventilation for proper cooling | Replacement of breather Ones in a year FOC |

| OLTC functions ( If Available ) | Tightening or refitting of HV / LV terminalsAnd cables and improving contact surfacewith reduce resistance values |

| I.R. Value Check | Inspection & Testing of all Tripping and Earthing system |

| Check Magnetic balance (If Required) | Transformer outer surface cleaning & de-rusting. |

| Ratio Test On All Taps (If Required) | |

| Winding Resistance (If Required) | |

| Polarization Index (PI) (If Required) | |

| BDV Of Oil | |

| Reporting Of any abnormality during operation. |

Stay Tuned for the Future

As we continue to integrate IoT technology into our AMC offerings, Trafo Power remains dedicated to providing cutting-edge solutions for transformer maintenance. Keep an eye out for these advancements as we work towards enhancing the efficiency, safety, and performance of transformers across industries.